A piston engine is a very complex machine and no engine is equal to another one.

While having a talk with a mechanic, he told me that a Turbo Commander based at the local airport (powered with a carburated turbocharged engine) is so difficult to start up that if you use the checklist ad do exactly what they report you will end up flooding the engine. He also said that, after some experience, the pilot ended up with his custom startup checklist.

The TSIO-520-R of the Cessna TC210M is not that difficult to manage but it has its own character, fully simulated by REP.

For example, we learned that it always require a little bit of priming, even when it’s warm. Of course, the priming should be more aggressive when it’s cold.

If you prime the engine correctly it will fire up in 2 or 3 prop revolutions.

Another thing that we learned about is the behavior induced by the position of the fuel pipelines above the cylinder heads.

As the pipelines are just above the cylinders, when you turn off the engine the cylinders’ heat warms up the fuel pipelines and transforms the fuel to vapour. This is called vapour lock and causes a lot of headaches to the pilot who wants to startup the engine after 10-15 minutes from the last shut down.

In that case the engine would fire up normally and then die because of the fuel vapour that suffocate the combustion process.

There are many different ways to solve the vapour lock problem, all involving the use of the electrical fuel pump to clear the fuel pipelines from any trace of vapour.

As an example, before starting the engine you may want to close the mixture and turn on the fuel pump for 30-40 secs. This will recirculate fresh air into the fuel pipelines, removing the vapour lock.

Another way is to inject a little bit of fuel in the cylinders using the fuel pump, then start the engine and turn on the pump for few seconds when the engine is firing. This will clear the fuel pipelines but, hey, you have to be very quick to turn on and then off the pump as soon as possible or you will flood the engine!

Speaking of electrical fuel pump, like many other Cessnas, when flying the C210 you should use it only for priming before startup. During the other phases of flight you are supposed not to use it.

If you turn on the pump when the engine is running at low RPMs, you will flood it. You hear it sputting and then the combustion starts to be non-optimal until the moment it dies.

The cylinders combustion process is simulated through their compression too. Specifically, since the TSIO-520-R is a turbosupercharged engine, its compression is 7.5:1, lower than its normally aspirated counterpart.

The cylinder compression causes the propeller to rotate around specific “detention points” in which the cylinder compression is in a stable position. In this video you can see an example of that.

Simulating an engine means simulating the proper thrust too. This is where REP provide the most to X-Plane. X-Plane, in fact, does not provide the correct power output in many cases.

Those of you that currently own the Carenado C210 may do a simple test:

- Load the plane

- Go to “Settings”, “Data input & output” and select “Engine power”, this will show a small box with the current engine power expressed in HP.

- Start the engine.

- Read the engine power at many different RPM and MAP settings.

- Check the power values against the performance tables provided with the aircraft.

The result of this test is that the default engine power is much overrated or underrated in all of those settings except the full throttle/full rpm setting, at which the engine erogates 310HP.

REP corrects this behavior and make sure that the engine always provides the correct output.

An engine simulated at this level of precision provides another very important feature: a correct fuel burning ratio.

I’ve personally tested that with REP the engine burns the correct amount of avgas at any altitude at any power setting!

Now there is only one thing that I did not mention: the turbocharger.

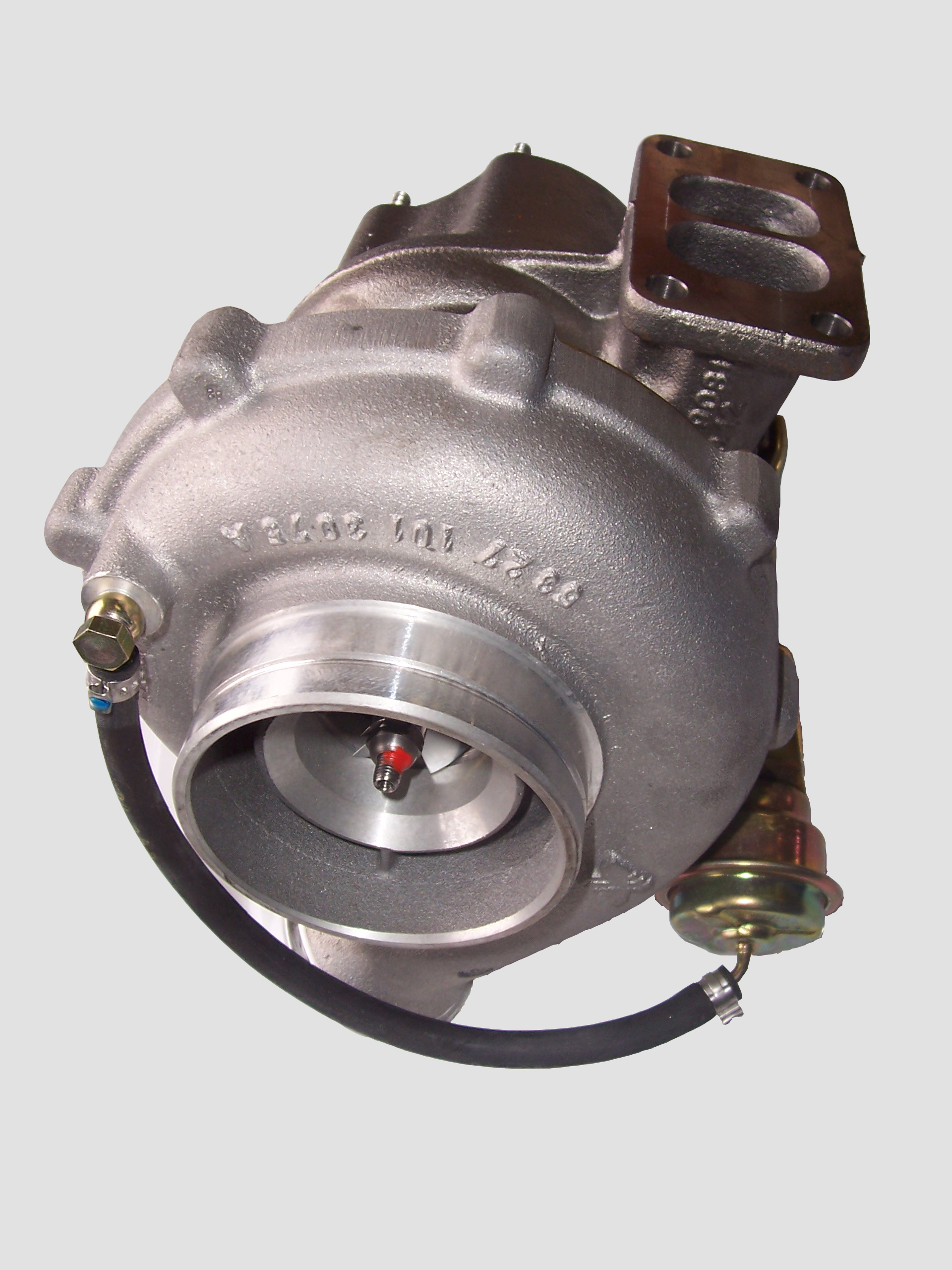

It consists in a small turbine powered by the engine’s exhaust gas. The gas spins the turbine that sucks in fresh air from the other side and compress it, pushing it inside the engine.

This allow the engine to maintain its power at high altitude. The Continental TSIO-520-R can provide 310HP up to 20.000 feet.

A turbocharger has, anyway, its downsides. For example, if not driven by a wastegate it may blow up your engine if you go over its MAP limit (in this case 36.5 inHg).

The TSIO-520-R features an automatic waste gate that dumps the excess of compression to avoid an engine overboost.

The automatic wastegate also keeps your MAP constant! This is a very nice feature during climbs and descents.

You just set your climb power after takeoff and then the automatic wastegate does the rest keeping your settings.

This autowastegate is oil driven using the same oil that lubrificates the engine. It opens through a spring and closes thanks to the engine’s oil pression.

So, what happens when the oil is cold and not fluid? When you push the throttle the spring opens the waste gate and the MAP goes up very fast but then, when the gate should stop to avoid the engine overboost, the oil is not fluid enough to provide a fast reaction and so you would likely overboost the engine.

A tip to avoid this problem? Warm up your engine before takeoff!

Pingback:Introducing the Reality Expansion Pack | SimCoders.com

Pingback:REP: Every startup is different - SimCoders.com